The rapid adoption of electric and hybrid vehicles on Singapore’s roads presents a substantial opportunity, yet it also introduces new operational complexities for automotive workshops. The inherent risks of working with advanced high-voltage systems-from personal safety concerns to the potential for damaging irreplaceable components-can create significant hesitation. This uncertainty is a barrier to growth. Mastering safe and professional high voltage system diagnostics is therefore no longer an optional skill but a critical competency for any forward-thinking automotive business seeking to remain competitive.

This definitive guide provides a structured, safety-first methodology designed for the professional technician. We will detail a step-by-step process to confidently identify and diagnose common faults, ensuring both personal safety and the integrity of the vehicle’s systems. By implementing these advanced procedures, you will build the technical capabilities required to expand your service offerings, enhance your workshop’s profitability, and establish your facility as a leader in the modern automotive ecosystem.

Key Takeaways

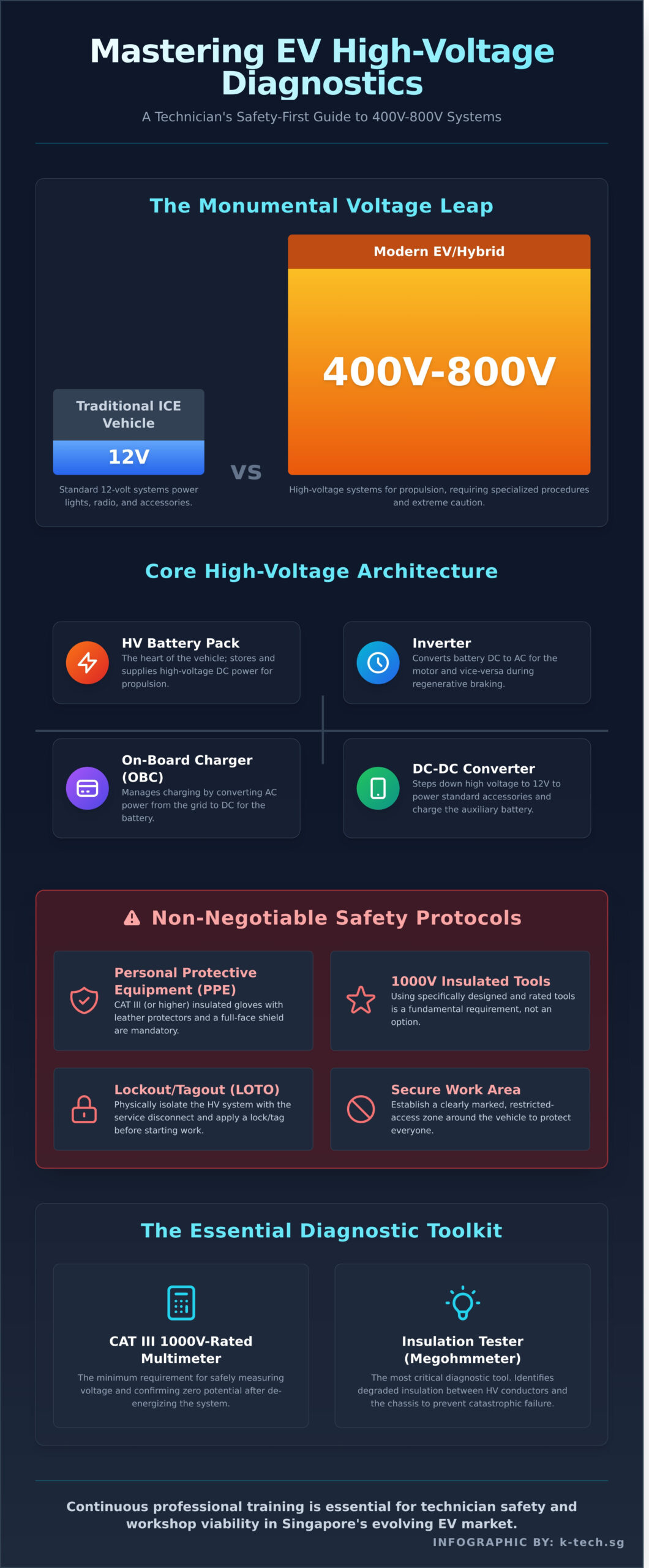

- Master the non-negotiable safety protocols and fundamental architecture of 400V-800V systems before attempting any diagnostic work.

- Identify the essential, insulated tools required for high-voltage work and understand why standard workshop equipment is both inadequate and hazardous.

- Implement a structured, step-by-step methodology for high voltage system diagnostics to move from initial complaint to accurate fault isolation efficiently.

- Gain the technical knowledge to diagnose faults within the HV battery pack, including the critical distinction between State of Health (SOH) and State of Charge (SOC).

- Recognise why continuous professional training is essential for technician safety and workshop viability in Singapore’s rapidly evolving EV market.

Fundamentals: Understanding EV High-Voltage Architecture and Safety

The automotive industry’s transition from traditional 12-volt internal combustion engine (ICE) systems to advanced Electric Vehicle (EV) architectures operating between 400V and 800V represents a monumental shift in vehicle technology. This evolution in electric vehicle technology mandates a complete re-evaluation of diagnostic and service procedures. For the modern technician, proficiency in high voltage system diagnostics begins not with the fault code, but with an unwavering commitment to safety. It is the non-negotiable first principle that underpins every action taken on an EV.

The fundamental objective before any diagnostic work can commence is to de-energize the system, verify that it is at zero potential, and only then proceed with the diagnosis. This methodical process mitigates the significant risks associated with high-voltage direct current (DC). Vehicle manufacturers universally use bright orange cabling and clear warning labels to visually identify all high-voltage components and conduits, serving as a constant and critical reminder of the potential hazards.

Key Components of the High-Voltage System

A comprehensive understanding of the core components is essential for effective diagnostics. The high-voltage system is an integrated ecosystem composed of several key modules:

- The HV Battery Pack: Acting as the heart of the vehicle, this large lithium-ion battery assembly stores and supplies the high-voltage DC power required for propulsion and other systems.

- The Inverter: This critical unit converts the battery’s DC power into three-phase alternating current (AC) to drive the electric motor. It also converts AC back to DC during regenerative braking to recharge the battery.

- The On-Board Charger (OBC): The OBC manages the charging process by converting AC power from the grid (e.g., a home or public charging station) into DC power to replenish the HV battery.

- The DC-DC Converter: This component functions like a traditional alternator, stepping down the high voltage from the main battery pack to a lower voltage (typically 12V) to power the vehicle’s standard accessories and charge the 12V auxiliary battery.

Essential High-Voltage Safety Protocols

Adherence to established safety protocols is mandatory. Failure to comply can result in severe injury or fatality. Every procedure for high voltage system diagnostics must incorporate these measures:

- Personal Protective Equipment (PPE): Technicians must wear correctly rated PPE, including CAT III (or higher) insulated gloves with leather protectors and a full-face shield to protect against arc flash.

- Insulated Tools: Using tools specifically designed and rated for 1000V is not optional; it is a fundamental requirement for preventing electrical shock.

- Lockout/Tagout (LOTO) Procedures: Before any work begins, the high-voltage system must be physically isolated using the vehicle’s service disconnect. A lock and tag are applied to prevent accidental re-energization.

- Secure Work Area: A clearly marked and restricted-access zone must be established around the vehicle to ensure the safety of the technician and others in the workshop.

The Essential Toolkit for High-Voltage System Diagnostics

Attempting to service electric or hybrid vehicles with a standard workshop toolkit is not only ineffective but also poses a severe safety risk. The elevated voltages and complex digital systems demand specialized equipment designed for accuracy and, most importantly, technician safety. Effective high voltage system diagnostics depends on a dedicated set of tools, which can be broadly divided into two critical categories: advanced measurement instruments and essential safety equipment. The operational integrity of this equipment, maintained through regular inspection and calibration, is non-negotiable.

Category-Rated Multimeters and Insulation Testers

Precise measurement is the cornerstone of diagnostics. A CAT III 1000V-rated multimeter is the minimum requirement for safely and accurately measuring voltage, confirming the absence of voltage after de-energizing, and testing resistance or continuity in HV circuits. However, the most critical diagnostic tool is the insulation tester, or megohmmeter. This device applies a high-voltage, low-current signal to test for insulation breakdown between HV conductors and the vehicle chassis. Identifying degraded insulation early prevents catastrophic short circuits, protects sensitive components, and ensures the vehicle’s electrical safety.

Advanced EV Diagnostic Scan Tools

Standard OBD2 scanners are insufficient for the complexities of modern EVs. A professional workshop requires an advanced diagnostic platform capable of deep system communication. These tools go beyond generic codes to:

- Access and interpret manufacturer-specific high-voltage DTCs.

- Analyze live data streams from the Battery Management System (BMS), including individual cell voltages, temperatures, and state of health.

- Perform active tests to command components like HV contactors, cooling pumps, and relays to verify their functionality.

Advanced platforms, such as those developed by Autel, provide the deep system integration required for comprehensive analysis and accurate fault finding in complex EV architectures.

Safety and De-energizing Equipment

Before any diagnostic measurements are taken, the technician’s safety must be secured. This foundational layer of equipment is the first line of defense against electrical hazards.

- HV Glove and Liner Kit: Class 0 insulated gloves, rated for 1000V, are mandatory PPE. They must be visually inspected before every use and professionally tested periodically.

- Service Disconnect Plug: This is the primary mechanism for physically isolating the high-voltage battery from the rest of the vehicle. Understanding its location and proper removal procedure is the first critical step in any service protocol.

- Voltage Proximity Detectors: A non-contact “live wire” tester provides a quick, preliminary safety check to verify that high voltage is not present in a component or area before physical contact is made.

A Step-by-Step Process for Diagnosing HV Faults

A structured workflow is fundamental to effective high voltage system diagnostics. When a vehicle presents with a warning such as ‘High Voltage System Failure,’ a methodical, ‘test, don’t guess’ approach is non-negotiable for ensuring technician safety and achieving an accurate diagnosis. This process combines advanced digital analysis with meticulous physical verification. Adherence to Original Equipment Manufacturer (OEM) service information at every stage is paramount for a safe and successful outcome.

Step 1: Initial Scan and DTC Analysis

The diagnostic process begins by connecting an advanced EV-capable scanner to the vehicle’s OBD-II port. This initial step is to retrieve all Diagnostic Trouble Codes (DTCs) from the high-voltage system modules. Interpreting these codes provides the first critical clues: a P0AA6 code suggests an isolation fault, while other codes might point directly to a failing contactor or an imbalance in battery cell voltages. Reviewing live data from the Battery Management System (BMS) offers further insight into cell health and system status before any physical intervention.

Step 2: De-energize the System and Verify Zero Voltage

Safety is the primary concern before proceeding with physical tests. Following the precise OEM procedure, de-energize the system by removing the service disconnect or plug. It is critical to wait for the specified time (typically 5-10 minutes) to allow high-voltage capacitors to discharge fully. Using a CAT III (or higher) rated multimeter and appropriate PPE, perform a zero-voltage test at designated points, such as the inverter input. The ‘live-dead-live’ verification method-testing the meter on a known live source, testing the HV circuit, then re-testing on the live source-confirms the tool is functioning and the system is truly de-energized.

Step 3: Performing Insulation Resistance Tests

Once the system is verified as safe, insulation resistance testing can commence. This phase of high voltage system diagnostics requires a megohmmeter (insulation tester) to detect current leakage between the high-voltage circuits and the vehicle chassis. By systematically isolating sections of the HV circuit-such as the battery pack, inverter, and high-voltage cabling-the fault can be pinpointed. Common culprits for insulation breakdown include:

- Damaged or chafed high-voltage wiring insulation

- An internal fault in the electric A/C compressor

- A short in the high-voltage cabin heater

- Moisture ingress into a connector or component

This isolation technique prevents unnecessary replacement of major components and ensures a precise, efficient repair.

Advanced Diagnostics: Focusing on the HV Battery Pack

The high-voltage (HV) battery pack is the most critical and expensive component within any electric or hybrid vehicle. With replacement costs in Singapore often exceeding S$15,000, precise diagnostics are not just a technical requirement but a financial necessity. A common point of confusion is the difference between State of Charge (SOC), which is the battery’s current energy level (like a fuel gauge), and State of Health (SOH), which represents its long-term degradation and ability to hold a charge. Effective high voltage system diagnostics focus on SOH to determine the true condition of the battery, preventing premature and costly replacements.

Analyzing Battery Management System (BMS) Data

The Battery Management System (BMS) acts as the brain of the HV battery, monitoring and controlling its operation. Using an advanced diagnostic scanner, technicians can access a wealth of live data from the BMS, including individual cell voltages, module temperatures, and resistance values. A key diagnostic indicator is cell imbalance, where one or more cells show a significantly different voltage from the others. This imbalance can trigger fault codes, reduce vehicle range, and indicate internal cell degradation. The scanner allows technicians to monitor the BMS’s cell balancing function, which actively works to equalize charge across all cells.

Diagnosing Contactor and Pre-charge Resistor Faults

Main contactors are heavy-duty relays that connect and disconnect the HV battery from the rest of the vehicle’s high-voltage system. A common failure mode is a contactor becoming stuck open or closed, which prevents the vehicle from starting or shutting down the HV system correctly. A professional scanner can often command the contactors to open and close, while a digital multimeter (DMM) can be used (following all safety protocols) to verify their physical state. The pre-charge resistor works with a smaller contactor to slowly charge the inverter capacitors, preventing a damaging inrush of current when the main contactors close. A failure in this circuit will prevent the system from energizing.

Interpreting Common Battery-Related DTCs

While there are hundreds of potential Diagnostic Trouble Codes (DTCs), several are fundamental to HV battery diagnostics:

- P0AA6 – Hybrid/EV Battery Voltage System Isolation Fault: This critical code indicates a loss of electrical isolation between the high-voltage circuit and the vehicle’s chassis, posing a significant safety risk that must be addressed immediately.

- P0D27 – Battery Cell Voltage Low/High: This code points directly to an issue with a specific cell, confirming the cell imbalance identified through BMS data analysis. It often signifies a failing cell that requires further investigation.

- P0C78 – Drive Motor Inverter Temperature Sensor Circuit: Although related to the inverter, this DTC is vital for battery health. Inverter overheating can be caused by issues within the HV system and can, in turn, damage other high-voltage components.

Mastering these advanced diagnostic techniques is essential for any modern workshop. Equipping your team with the right tools and training for comprehensive high voltage system diagnostics ensures accurate, safe, and cost-effective service. For more information on professional diagnostic equipment, explore the integrated automotive solutions at k-tech.sg.

Upskilling for Success: The Importance of Professional Training

In Singapore’s rapidly advancing automotive sector, the transition to electric vehicles (EVs) presents both a significant opportunity and a technical challenge. For a workshop to remain viable and competitive, continuous professional development is no longer optional-it is a strategic necessity. The sophisticated architecture of modern EVs means that mastering advanced skills, particularly in high voltage system diagnostics, is fundamental to ensuring technician safety, operational efficiency, and long-term business growth.

An investment in professional training yields substantial returns. Technicians equipped with specialized knowledge can diagnose complex faults with greater speed and accuracy, reducing vehicle-on-hoist time and increasing workshop throughput. This proficiency prevents costly misdiagnoses-a critical concern when dealing with expensive components like battery packs and power electronics. Furthermore, certified expertise builds immense client trust, positioning your workshop as a credible leader in the EV service industry.

Why On-the-Job Learning Isn’t Enough for HV Systems

While practical experience is valuable, the inherent dangers of high-voltage systems demand a formal, structured approach to learning. The lethal voltages present in EVs leave zero margin for error, making certified safety protocols non-negotiable. Moreover, effective diagnostics require a deep, theoretical understanding of electrical principles that cannot be fully absorbed through informal observation. Professional certification provides this foundational knowledge and serves as a crucial assurance of competence to your customers.

Choosing a High-Quality EV Training Program

Selecting the right training partner is critical to developing genuine technical capabilities. When evaluating programs, prioritize the following criteria:

- Industry-Recognized Accreditations: Look for qualifications from globally respected bodies, such as the Institute of the Motor Industry (IMI), which guarantee a high standard of training.

- Practical, Hands-On Training: Theory must be paired with practice. Ensure the program provides substantial time working on actual EVs with professional-grade diagnostic tools and safety equipment.

- Comprehensive Curriculum: The course should cover the full spectrum of EV service, including essential safety procedures, advanced component testing, and complete high voltage system diagnostics.

Investing in the right skills is the most effective way to secure a competitive advantage in the evolving automotive ecosystem. Explore K-Tech’s IMI-accredited EV technical training programs to equip your team with the expertise needed to excel.

Advancing Your Workshop’s Capabilities in EV Diagnostics

Mastering the complexities of modern electric vehicles is an achievable goal, grounded in a fundamental understanding of HV architecture and an unwavering commitment to safety protocols. A systematic, step-by-step approach, supported by specialized equipment, is critical for accurately performing high voltage system diagnostics and resolving faults efficiently. Ultimately, continuous professional development is the key component that ensures technicians can confidently and competently navigate the evolving landscape of EV technology, turning complex challenges into opportunities for growth.

To elevate your workshop’s technical capabilities and secure a competitive advantage, partnering with an industry leader is paramount. As Singapore’s exclusive Autel distributor and an IMI UK accredited Technical Training Academy, K-Tech Auto Solution provides the integrated, end-to-end solutions your business requires. We are the specialized provider of EV and hybrid vehicle solutions that leading automotive businesses trust to enhance their operational efficiency and service quality.

Equip your workshop with advanced Autel EV diagnostic tools and training. Contact K-Tech today.

Embrace the future of automotive service with confidence and position your business for sustainable growth in the electric era.

Frequently Asked Questions

What is a high-voltage interlock loop (HVIL) and how do you test it?

The High-Voltage Interlock Loop (HVIL) is a critical safety circuit designed to protect technicians by de-energizing the high-voltage system if any service cover or connector is opened. It operates on a low-voltage signal, typically 5V or 12V. Testing involves using a multimeter to confirm continuity across the entire loop. A break in this continuity, registered as an open circuit, indicates a disconnected component that must be identified and secured before re-energizing the system.

Can I use my standard workshop multimeter for high-voltage diagnostics?

No, a standard workshop multimeter is inadequate and extremely dangerous for high-voltage applications. Technicians must use a multimeter with a minimum CAT III 1000V rating for any direct contact measurements. These specialized instruments are engineered to withstand high-energy transients and prevent arc flashes, ensuring technician safety. Using improperly rated equipment creates a severe risk of electrocution and equipment damage, compromising the integrity of professional high voltage system diagnostics.

What are the first signs of an insulation breakdown in an EV’s high-voltage system?

Initial indicators of insulation breakdown often include Diagnostic Trouble Codes (DTCs) related to isolation faults. The vehicle may also display a high-voltage system warning light or enter a reduced power mode. In some instances, a vehicle may fail to start or shut down unexpectedly. These symptoms necessitate immediate and advanced high voltage system diagnostics using a certified insulation tester, or megohmmeter, to accurately confirm and locate the source of the fault.

How often should insulated gloves and tools be tested and replaced?

Insulated gloves require a daily visual inspection and an air leak test before every use. Professional dielectric testing is mandatory every six months from the date they are first issued for service. Insulated hand tools must also be visually inspected before each use for any damage to the insulation layer, such as cracks, cuts, or gouges. Any tool with compromised insulation must be immediately removed from service and replaced to maintain full safety compliance.

Is specific certification required to work on EV high-voltage systems in Singapore?

Yes, specific training and certification are essential for technicians in Singapore. While direct government regulation is evolving, industry best practices and workplace safety legislation mandate documented competency. Certifications like the Institute of the Motor Industry (IMI) International Level 3 Award in Electric/Hybrid Vehicle System Repair and Replacement are globally recognized benchmarks. They validate a technician’s capability to perform these high-risk tasks safely and effectively within the local automotive ecosystem.

What is the difference between a CAT II and a CAT III rated multimeter?

The CAT (Category) rating defines the level of overvoltage protection a multimeter provides against transient spikes. A CAT II meter is rated for single-phase, receptacle-connected loads, such as standard appliances. A CAT III rated meter is designed for three-phase distribution systems, including fixed installations like commercial panels and motors. For EV high-voltage work, a CAT III 1000V rating is the minimum professional requirement, offering superior protection against the high-energy transients inherent in these advanced systems.