The rapid evolution of automotive technology presents a significant challenge for independent workshops across Singapore. As Electric Vehicles (EVs) and complex Advanced Driver-Assistance Systems (ADAS) become standard, many workshop owners face the growing risk of falling behind, losing business to main dealerships with proprietary tools, and struggling to source technicians with the necessary advanced skills. This uncertainty can make strategic investment in new equipment and training feel like a high-stakes gamble.

However, this technological shift is not a threat, but a substantial opportunity for workshops prepared to adapt. Navigating this new landscape requires a clear, strategic understanding of the future of auto repair. This article serves as a professional guide to the critical transformations shaping our industry. We will analyse five key trends, from the rise of remote diagnostics to the essentials of high-voltage battery servicing, providing a clear roadmap for forward-thinking businesses. Discover the essential tools, technical capabilities, and training required to not only stay competitive but to become a leader in the next generation of automotive service and ensure your workshop’s sustainable growth.

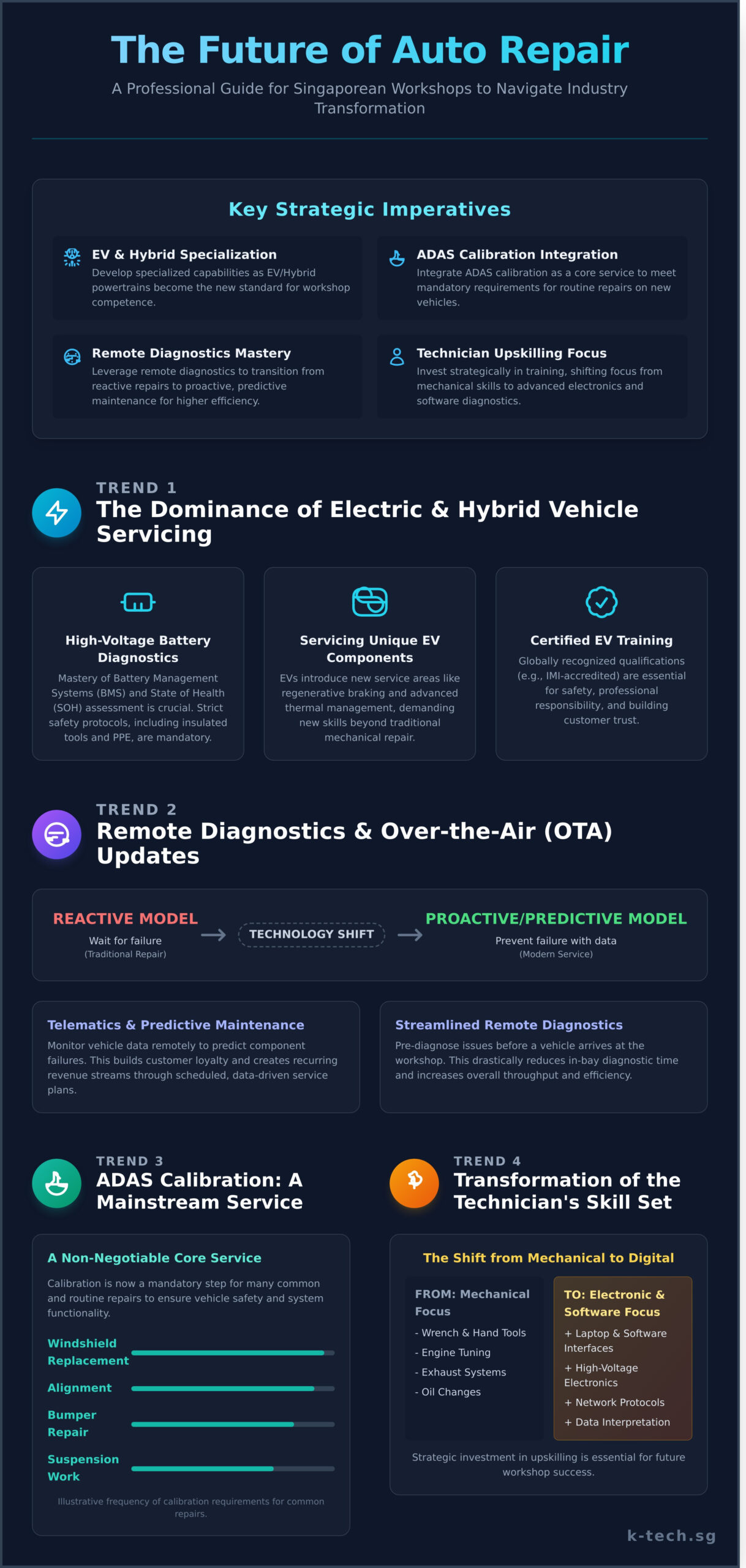

Key Takeaways

- Develop specialized capabilities for Electric and Hybrid Vehicle servicing, as this powertrain transition now dictates the standard for modern workshop competence.

- Integrate ADAS calibration into your core service offerings to meet the mandatory requirements of many routine repairs on new vehicles in the Singapore market.

- Leverage remote diagnostics to transition your service model from reactive repairs to proactive, predictive maintenance, enhancing operational efficiency.

- The future of auto repair demands a strategic investment in upskilling technicians, shifting the focus from mechanical skills to advanced electronics and software diagnostics.

Trend 1: The Dominance of Electric & Hybrid Vehicle Servicing

The automotive industry in Singapore and globally is undergoing a monumental transition. The accelerated shift from internal combustion engines (ICE) to sophisticated electric and hybrid powertrains is no longer a distant forecast; it is the current reality shaping the future of auto repair. This evolution presents an unprecedented growth opportunity for workshops that invest in new competencies and advanced technologies. The traditional focus on oil changes, engine tuning, and exhaust systems is rapidly being replaced by a demand for expertise in high-voltage battery health, thermal management, and complex vehicle software ecosystems.

High-Voltage Battery Diagnostics and Maintenance

The high-voltage battery pack is the core component of any electric vehicle. Servicing it effectively requires a deep understanding of its integrated Battery Management System (BMS), which governs performance and safety. Technicians must be proficient with specialized diagnostic equipment to accurately assess a battery’s State of Health (SOH). Furthermore, engaging with these high-voltage systems demands strict adherence to safety protocols, including the mandatory use of insulated tools and appropriate personal protective equipment (PPE) to mitigate extreme electrical hazards.

Servicing Unique EV Components

EVs introduce a range of components that require entirely new service methodologies. Regenerative braking systems, for instance, have different inspection and maintenance procedures compared to conventional hydraulic systems. Advanced thermal management systems, crucial for regulating battery and motor temperatures, represent another new and critical service area. While EVs possess fewer moving parts, their operational complexity is significantly higher due to intricate electronics that often integrate with other vehicle functions, such as Advanced driver-assistance systems (ADAS).

The Necessity of Certified EV Training

Attempting to service high-voltage systems without formal, certified training is exceptionally dangerous and professionally irresponsible. Globally recognized qualifications, such as those provided by IMI-accredited courses, deliver the essential technical knowledge and safety standards required to operate competently. Workshops that employ certified EV technicians not only ensure the safety of their staff and clients but also establish a significant competitive advantage, positioning their business as a credible and forward-thinking leader in an evolving automotive landscape.

Trend 2: The Rise of Remote Diagnostics and Over-the-Air (OTA) Updates

The modern vehicle is no longer a purely mechanical machine; it is a sophisticated, connected computer on wheels. This connectivity is a cornerstone of the future of auto repair, enabling vehicles to transmit vast amounts of operational and health data in real-time. This paradigm shift transforms the traditional repair model from being reactive-addressing failures after they occur-to being proactive and even predictive. For workshops in Singapore, mastering these new digital workflows is not an option but a necessity for sustained operational efficiency and market leadership.

Telematics and Predictive Maintenance

Advanced telematics systems allow workshops to monitor vehicle data remotely, analysing performance metrics to predict potential component failures before they escalate into critical issues. This capability enables the creation of proactive maintenance plans for both individual clients and commercial fleets, building significant customer loyalty. By offering scheduled, preventative service based on real-world data, workshops can establish recurring revenue streams and position themselves as indispensable partners in their clients’ vehicle ownership experience.

Performing Diagnostics from a Distance

The evolution of diagnostic technology now permits technicians to access and analyse a vehicle’s onboard systems from the workshop, even while the car is miles away. By using professional remote diagnostic tools, a technician can pre-diagnose an issue before the vehicle physically arrives. This dramatically streamlines the repair process, reducing diagnostic time in the bay and increasing overall workshop throughput. Technicians must now be proficient not just with wrenches, but with software interfaces, network protocols, and data interpretation.

Navigating ‘Right to Repair’ and Data Access

A significant challenge in this new landscape is the increasing restriction of vehicle data by Original Equipment Manufacturers (OEMs). As vehicles become more complex, especially with the integration of features like those detailed in the NHTSA’s overview of safety technologies, access to diagnostic and repair information is often gated. For independent workshops, investing in professional, multi-brand diagnostic equipment with broad vehicle coverage is essential. This strategic investment ensures the technical capability to service a wide range of modern vehicles, securing a workshop’s role in the evolving automotive ecosystem.

Trend 3: ADAS Calibration as a Mainstream Service

The proliferation of Advanced Driver-Assistance Systems (ADAS) has fundamentally altered the landscape of vehicle maintenance. Once reserved for luxury models, features like lane-keeping assist, adaptive cruise control, and automatic emergency braking are now standard on most new vehicles in Singapore. This shift makes ADAS calibration a non-negotiable component in the future of auto repair. For workshops, failing to correctly calibrate these intricate systems after a service introduces significant safety and liability risks. Conversely, for those properly equipped and trained, it represents a high-demand, high-value revenue stream essential for modern operational success.

When is ADAS Calibration Required?

A precise ADAS calibration is not just an optional check; it is mandated by Original Equipment Manufacturer (OEM) procedures following numerous common repairs. Any procedure that can alter a sensor’s position, even by a millimetre, necessitates a full system calibration to ensure functionality. Key triggers include:

- Windscreen Replacement: Cameras mounted on the windscreen must be recalibrated.

- Alignment and Suspension Work: Changes to the vehicle’s ride height or thrust angle directly affect ADAS sensor readings.

- Collision Repair: Any impact, particularly to bumpers or grilles where radar and lidar sensors are housed, requires immediate calibration.

- Sensor Disturbance: Any time a sensor, camera, or its mounting bracket is removed, replaced, or disturbed.

Essential Equipment for Accurate Calibration

Performing professional-grade ADAS calibration demands a significant investment in specialized equipment. A comprehensive setup includes a combination of targets, a mounting frame, and an advanced diagnostic scan tool capable of initiating the calibration process. The complexity of these systems is driving a wider industry shift, as confirmed by current remote vehicle diagnostic market trends which point to increasing vehicle computerisation. Furthermore, the workshop environment itself is critical: a perfectly level floor, consistent and controlled lighting, and a clearly marked, unobstructed space are all prerequisites for an accurate, OEM-compliant service.

The Critical Role of Technician Training

Advanced equipment is only one part of the equation. The technician’s skill is paramount to a successful and safe calibration. Every OEM has precise, model-specific procedures that must be followed without deviation. Proper training ensures that technicians understand the nuances of different systems, can interpret diagnostic data correctly, and can perform the calibration with accuracy. This professional competence is the ultimate safeguard for both the vehicle owner and the workshop, protecting against post-repair incidents and operational liability. To meet this growing industry need, specialised training is no longer optional but a core requirement for sustained success. Explore our IMI-accredited ADAS training courses.

Trend 4: The Transformation of the Automotive Technician’s Skill Set

The role of the automotive technician is undergoing its most significant evolution in a century. As vehicles transform into sophisticated computers on wheels, the traditional mechanical skillset, while still important, is no longer sufficient. The modern workshop professional must be a hybrid expert, blending deep mechanical knowledge with advanced capabilities in electronics, software, and data analysis. This shift is a defining characteristic of the future of auto repair, and workshops that fail to adapt risk being left behind by an industry facing a critical shortage of technicians equipped with these next-generation skills.

From ‘Mechanic’ to ‘Master Technician’

The transition from a ‘mechanic’ to a ‘master technician’ is marked by a fundamental change in core competencies. Today, a deep understanding of electrical principles, vehicle network topology like CAN bus systems, and high-voltage safety protocols for EVs is non-negotiable. Proficiency is now measured by the ability to operate advanced diagnostic software, interpret complex data streams, and efficiently research OEM technical service bulletins to formulate an accurate repair strategy. The wrench is now just one tool in an arsenal dominated by laptops and diagnostic interfaces.

The Business Case for Continuous Professional Development

For workshop owners in Singapore, investing in continuous training is not an expense but a strategic imperative for sustainable growth. Upskilling your technical team yields direct returns on investment by enhancing operational efficiency and expanding service capabilities. A highly-trained team can:

- Increase Productivity: Accurately diagnose complex electronic faults faster, reducing diagnostic time and increasing job throughput.

- Boost Profitability: Confidently take on high-value jobs like ADAS calibration and EV battery diagnostics that other workshops turn away.

- Improve Retention: Offering professional development demonstrates a commitment to employee growth, helping to retain top talent in a competitive market.

- Enhance Reputation: Certified technicians build customer trust and solidify your workshop’s position as a market leader.

Building a Culture of Lifelong Learning

Creating an environment that prioritizes continuous learning is the most critical investment a workshop can make in the future of auto repair. Encourage and support your technicians in pursuing globally recognised certifications in high-growth areas such as Electric Vehicles, Advanced Driver-Assistance Systems (ADAS), and advanced diagnostics. Partnering with a trusted, IMI-accredited training provider ensures a structured and effective development path. Ultimately, your most valuable asset is not your equipment, but the advanced technical capabilities of your team. Explore how an integrated training solution can prepare your workshop for the challenges ahead.

Secure Your Workshop’s Position in the Future of Auto Repair

The automotive landscape is undergoing a significant transformation, driven by the proliferation of electric vehicles and the increasing complexity of onboard systems. Mastering advanced diagnostics and ADAS calibration is no longer optional; it is fundamental to operational excellence and sustainable growth for modern workshops in Singapore. The technician’s role is evolving, demanding a new level of technical proficiency to service these advanced vehicles.

As a trusted partner for workshops, fleet operators, and educational institutions across Singapore, K-Tech Auto Solution provides an integrated automotive ecosystem to ensure your success. From our position as the exclusive Singapore distributor for Autel diagnostic solutions to our status as an Institute of the Motor Industry (IMI UK) Accredited Training Academy, we deliver the advanced equipment and professional training necessary to thrive. Prepare your workshop for the future. Contact us for a consultation on equipment and training.

Embrace the changes ahead with confidence and position your business as a leader in the next generation of automotive service.

Frequently Asked Questions

Will electric vehicles eventually eliminate the need for auto repair workshops?

On the contrary, the proliferation of electric vehicles (EVs) will transform, not eliminate, the auto repair industry. While EVs possess fewer traditional mechanical components, they introduce complex high-voltage battery systems, advanced electronics, and sophisticated software that require specialized diagnostic tools and technical training. Workshops must evolve their capabilities to service these systems, alongside standard components like brakes, suspension, and tires, ensuring their continued relevance in the automotive ecosystem.

How can independent workshops compete with dealerships that have proprietary OEM tools?

Independent workshops can achieve a competitive advantage by investing in advanced, globally recognized aftermarket diagnostic tools. Modern solutions, such as those from Autel, offer comprehensive, OEM-level capabilities across multiple brands, providing a superior return on investment. This, combined with continuous, IMI-accredited technical training, allows independent workshops to deliver high-quality, efficient service for a diverse range of vehicles, establishing a strong market position beyond single-brand dealership constraints.

What is the single most important investment a workshop can make to prepare for the future?

The single most critical investment for the future of auto repair is continuous technical training and upskilling for technicians. Technology evolves rapidly, and advanced equipment is only effective in the hands of skilled professionals. Investing in accredited programs, such as those certified by the Institute of the Motor Industry (IMI), ensures your team has the validated expertise to manage EV, ADAS, and complex diagnostic challenges, securing the workshop’s long-term operational viability and service excellence.

How much physical space is required to perform ADAS calibrations correctly?

The spatial requirements for accurate Advanced Driver-Assistance Systems (ADAS) calibration are dictated by OEM specifications and are non-negotiable for safety. A workshop typically requires a dedicated bay with a flat, level floor and a clear, unobstructed space of at least 10 metres by 7 metres. This area must be free from reflective surfaces and bright, direct sunlight to ensure the precision of the calibration equipment and the integrity of the sensor adjustments.

Are there government grants or support in Singapore for upskilling automotive technicians?

Yes, the Singapore government provides significant support for workforce development through various initiatives. Schemes like SkillsFuture Singapore (SSG) offer training grants and subsidies that can be applied to approved technical courses. Automotive businesses can leverage these programs to offset the cost of upskilling their technicians in critical areas like EV maintenance and ADAS calibration. K-Tech Auto Solution provides courses that are eligible for such funding, facilitating accessible, high-quality professional development.

How do Over-the-Air (OTA) updates affect the auto repair business model?

Over-the-Air (OTA) updates are reshaping the future of auto repair by enabling remote software fixes, potentially reducing visits for certain issues. However, this creates new service opportunities. Workshops are now essential for diagnosing problems that OTA updates cannot resolve, managing failed updates, and performing the necessary hardware replacements or calibrations that must follow a software change. This positions the modern workshop as a critical partner in validating and completing complex vehicle system integrations.